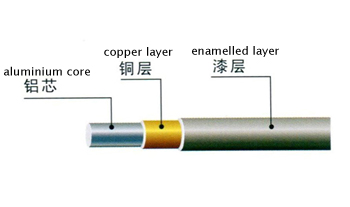

Enamelled Copper Clad Aluminium/CCA wire

Enamelled CCA wire is a new kind of magnet wire adopting CCA as conductor, which simultaneously has the features of copper's good electrical conductivity and aluminium's light weight.

Advantages

1. Light weight

CCA wire's density is one third of copper wire of same diameter, which effectively reduce the weight of cable and wire.

2. DC resistivity

CCA wire's DC resistivity is 1.5 times of copper wire, and CCA wire's weight is a half of copper wire when the resistance is same.

3. Soldering

The surface of CCA wire is claded with copper layer, so it can be soldered like copper wire, and there is no need of special treatment like aluminium wire.

Applications

1. Special electromagnetic wire applied in voice coils, CD driver

2. Electromagnetic wire for mobiles and watches

3. Electromagnetic wire for rotor coils of mini-motor

4. Electromagnetic wire for high frequency transformers

5. Electromagnetic wire for deflection coils of displayer

6. Electromagnetic wire for demagnetizing coil

7. Other electromagnetic wire

Characteristics Comparison

|

Property |

CCA wire |

Copper wire |

Aluminium wire |

|

Copper volume (%) |

15 |

100 |

0 |

|

Specific gravity (g/cm3) |

3.63 |

8.89 |

2.70 |

|

Length ratio under same diameter |

2.5:1 |

1:1 |

3.29:1 |

|

Conductivity (%IACS) |

70 |

100 |

62 |

|

DC resistivity (Ω.mm2/m) |

0.02462 |

0.01724 |

0.02740 |

|

Tensile strength (Mpa) |

95-135 |

215-265 |

68-107 |

|

Elongation (%) |

≥10 |

≥20 |

≥8 |

|

Windability |

good |

very good |

good |

|

Weight |

good |

bad |

very good |

|

Soldering |

very good |

very good |

bad |

|

DC resistance |

good |

very good |

good |

Characteristics of emamelled CCA wire

|

Size |

Max. Resistance |

Min. Breakdown Voltage |

Min. Elongation |

Scrape resistance | ||||

|

conductor |

ZUEW |

Ω/m( |

(V) |

(%) |

(N) | |||

|

diameter |

tolerance |

Min. insulation thickness |

Max. outer diameter |

Average |

Min. | |||

|

(mm) |

(mm) |

(mm) |

(mm) | |||||

|

0.040 |

±0.002 |

0.003 |

0.056 |

23595.44 |

500 |

5 |

- |

- |

|

0.050 |

±0.003 |

0.004 |

0.069 |

15424.09 |

950 |

5 |

- |

- |

|

0.060 |

±0.003 |

0.004 |

0.081 |

10486.86 |

950 |

5 |

- |

- |

|

0.070 |

±0.003 |

0.004 |

0.091 |

7590.07 |

950 |

5 |

- |

- |

|

0.080 |

±0.003 |

0.005 |

0.103 |

5746.64 |

1100 |

5 |

- |

- |

|

0.090 |

±0.003 |

0.005 |

0.113 |

4501.49 |

1100 |

5 |

- |

- |

|

0.100 |

±0.003 |

0.005 |

0.125 |

3621.19 |

1100 |

10 |

- |

- |

|

0.110 |

±0.003 |

0.005 |

0.135 |

2975.96 |

1100 |

10 |

- |

- |

|

0.120 |

±0.003 |

0.006 |

0.147 |

2488.99 |

1300 |

10 |

- |

- |

|

0.130 |

±0.003 |

0.006 |

0.157 |

2112.46 |

1300 |

10 |

- |

- |

|

0.140 |

±0.003 |

0.007 |

0.167 |

1815.32 |

1300 |

10 |

- |

- |

|

0.150 |

±0.003 |

0.007 |

0.177 |

1576.74 |

1300 |

10 |

- |

- |

|

0.160 |

±0.003 |

0.008 |

0.189 |

1382.28 |

1300 |

10 |

- |

- |

|

0.170 |

±0.003 |

0.008 |

0.199 |

1221.69 |

1300 |

10 |

- |

- |

|

0.180 |

±0.003 |

0.008 |

0.211 |

1087.55 |

1600 |

10 |

- |

- |

|

0.190 |

±0.003 |

0.008 |

0.221 |

974.34 |

1600 |

10 |

- |

- |

|

0.200 |

±0.003 |

0.008 |

0.231 |

877.94 |

1600 |

10 |

- |

- |

|

0.210 |

±0.003 |

0.008 |

0.241 |

795.16 |

1600 |

10 |

- |

- |

|

0.220 |

±0.004 |

0.008 |

0.252 |

730.28 |

1600 |

10 |

- |

- |

|

0.230 |

±0.004 |

0.009 |

0.261 |

667.08 |

1600 |

10 |

- |

- |

|

0.240 |

±0.004 |

0.009 |

0.274 |

611.75 |

1600 |

10 |

- |

- |

|

0.250 |

±0.004 |

0.009 |

0.284 |

563.02 |

1600 |

10 |

- |

- |

|

0.260 |

±0.004 |

0.009 |

0.294 |

519.89 |

1600 |

10 |

2.00 |

1.60 |

|

0.270 |

±0.004 |

0.009 |

0.304 |

481.54 |

1600 |

10 |

2.00 |

1.60 |

|

0.280 |

±0.004 |

0.009 |

0.314 |

447.28 |

1600 |

10 |

2.00 |

1.60 |

|

0.290 |

±0.004 |

0.009 |

0.324 |

416.55 |

1600 |

15 |

2.00 |

1.60 |

|

0.300 |

±0.005 |

0.010 |

0.337 |

391.52 |

2000 |

15 |

2.00 |

1.90 |

|

0.320 |

±0.005 |

0.010 |

0.357 |

343.38 |

2000 |

15 |

2.00 |

1.90 |

|

0.350 |

±0.005 |

0.010 |

0.387 |

286.26 |

2000 |

15 |

2.00 |

1.90 |

|

0.370 |

±0.005 |

0.010 |

0.407 |

255.75 |

2000 |

15 |

2.00 |

1.90 |

|

0.400 |

±0.005 |

0.011 |

0.439 |

218.37 |

2000 |

15 |

2.50 |

2.10 |

|

0.450 |

±0.006 |

0.011 |

0.490 |

172.83 |

2000 |

15 |

2.60 |

2.10 |

|

0.500 |

±0.006 |

0.012 |

0.542 |

139.62 |

2000 |

15 |

3.00 |

2.40 |

|

0.550 |

±0.006 |

0.012 |

0.592 |

115.13 |

2000 |

15 |

3.00 |

2.40 |

|

0.600 |

±0.008 |

0.012 |

0.644 |

97.22 |

2000 |

15 |

3.00 |

2.50 |

|

0.700 |

±0.008 |

0.013 |

0.746 |

71.15 |

2000 |

15 |

3.40 |

2.90 |

|

0.800 |

±0.010 |

0.015 |

0.852 |

54.59 |

2400 |

15 |

4.20 |

3.40 |

|

0.900 |

±0.010 |

0.016 |

0.956 |

43.01 |

2400 |

15 |

4.50 |

3.70 |

|

1.000 |

±0.010 |

0.017 |

1.062 |

34.76 |

2400 |

15 |

4.90 |

4.10 |

|

1.200 |

±0.010 |

0.020 |

1.246 |

24.06 |

2800 |

15 |

5.20 |

4.40 |

|

1.300 |

±0.010 |

0.021 |

1.368 |

20.47 |

2800 |

15 |

5.30 |

4.50 |

|

1.400 |

±0.010 |

0.022 |

1.468 |

17.63 |

2800 |

15 |

5.40 |

4.60 |

|

1.500 |

±0.010 |

0.023 |

1.570 |

15.35 |

2800 |

15 |

5.60 |

4.80 |

|

1.600 |

±0.010 |

0.023 |

1.670 |

13.48 |

3000 |

15 |

5.60 |

4.80 |

Copyright ©2012 WuXi Holysun Machinery Equipment Co., Ltd.All rights reserved. Technical support speed technology 速联科技